Posted: March 29, 2017

Outside of “Mr Clutch” you’ll be hard pressed to find a person, or group of people that spend a great deal of time thinking about that ‘thing’ typically operated by the pedal underneath your left foot that makes gear change possible. But clutches are an integral part of most vehicles (even those with an automatic transmission) and so it pays to know a bit about how they work so you can preserve the life of yours and save yourself a costly trip to the garage.

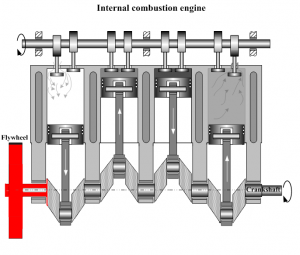

Simplified massively, a clutch has two discs. The first is a steel flywheel which you’ll see on the left of this image. This is attached to the crankshaft (the crankshaft converts the linear motion of the pistons into rotational energy).

The second is the clutch disc, also known as a splined friction disc or centre plate. This transmits drive from the engine to the gearbox input shaft. There’s also a pressure plate containing a sprung mechanism which is bolted to the flywheel to clamp the friction disc to the flywheel and onwards to an actuating mechanism.

In its resting position (i.e. before you put your foot on the clutch), the two discs are tightly clamped together. The action of putting your foot on the clutch releases the force generated by the pressure plate, enabling them to move apart. In doing so, you momentarily disengage the drive from the engine to the gearbox which allows you to change gear. Once you take your foot off the clutch pedal, the clamping force is reapplied and drive is resumed.

In modern racing cars and high performance road cars, it’s common to see a twin disc clutch. This includes two friction plates and gives double the clamping power when re-engaging with the flywheel. If you’re dealing with a car with over 500 horse power this is extremely beneficial, though it’s likely you’ll need to push down twice as hard on the clutch pedal to change gear.

Shortening the life of your clutch

If you’re someone who finds hill starts or parking in tight spaces a challenge, you may have been in situations when your engine is delivering sky-high revs but the car is only moving forward or backwards at one or two miles per hour. Typically in this situation, the driver has the clutch semi-depressed and that means that although the friction disc and the flywheel have come together, the lack of pressure between them is causing the discs to slip. If you’re finding the situation particularly challenging and it’s taking you quite a bit of time to get the manoeuvre done, you’ll probably start to smell the clutch burning as the friction between the slipping discs heats up the components. The unwanted heat soaks through the hydraulic actuating cylinder and could cause the hydraulic seals to give out. Even if this doesn’t happen, slipping the clutch in this manner can be compared to sanding down a piece of wood with a piece of glass /sand paper. Initially the paper is rough and full of grip, but as time goes on, the grip is worn away and you’re left with a smooth friction disc which is unable to grip the flywheel to create drive.

And that’s not the only situation where as a driver, you could be at risk of wearing your clutch. It’s important to pay particular attention to how early you press the gas down at the end of each gear change. Get on the gas too early before the friction disc is fully clamped to the flywheel and you will have a similar problem with clutch slip, friction, heat and a shortened clutch life.

Should I religiously push the clutch pedal all the way to the floor every time I change gears?

Every clutch will have a different bite point, some a lot lower than others. When driving on the road or on circuit you need to apply enough pressure and subsequently allow the pedal to travel far enough, to allow the friction disc to “free wheel” independently of the flywheel. If this is not achieved the clutch will “drag”. You’ll know if your clutch is dragging because you will find it difficult to engage gears because the gearbox is still rotating - albeit slowly. This typically results in the driver forcing the car into gear, potentially wearing out gearbox internals as well as shortening the life of the clutch.

I’ve heard you can perform a “clutchless gearshift” – how is that possible?

Yes, a clutchless gearshift is possible but definitely not recommended. Clutchless shifts require that the gear you are currently in and the gear you’re changing into are at a matched speed. This can only really be done at a low to moderate engine speed. The faster you go, the more difficult it becomes and of course, the amount of trial and error required to accomplish the task risks causing damage to your gearbox and drive train. There’s the safety aspect too. Your decision to change gear should be based on road conditions. If you’re having to focus your brain on matching gear speeds to accomplish a clutchless shift, you definitely won’t be thinking about planning for the hazards on the road ahead. Performing a clutchless gear change takes more time than an ordinary shift too, so that means more time with your hands off the steering wheel and a greater likelihood that you’ll end up coasting as the gear fails to engage, adding further to the demands on your concentration and cognitive skills.

Final Advice

If your driving promotes smooth precise gear changes and a considered application of the accelerator pedal, worry not. However if you’re missing the odd gear, feeling the revs rise but not getting an appreciable feeling of forward momentum, or visiting the garage too often for clutch changes, it may be time to take a look at your driving technique. Our core skills driving course could be just what you need.

Call: 01234 757 633

Email: info@catdrivertraining.co.uk

CAT Driver Training is the fast way to develop & improve authentic dynamic driving skill, technique & knowledge from the Best. OEM recognised driver training for individuals & the motor industry. As the leading UK based independent advanced performance driving skills company, we exist to make your driving experience even better. Explore your cars potential, fulfill your own. Coaching advanced road & track skills, safety driver training courses for individual driving enthusiasts & advanced driving for all facets of the motor industry. The only training company resident within UTAC's Millbrook Proving Ground in Bedfordshire, within easy reach of London, & all surrounding counties: Hertfordshire; Buckinghamshire; Oxfordshire; Nottinghamshire; Cambridgeshire; Norfolk; Suffolk; Essex; & Surrey. Clients travel from the World over & the UK to learn from the authentic evidence based dynamic driving & vehicle dynamic experts. | All Rights Reserved | Copyright 2005 – 2025

Some of the links we use are affiliate links. This means that, at no cost to you, CAT will earn an affiliate commission if you click through the link and finalise a purchase.

Designed by WHP

Coded and built by Prominent Media